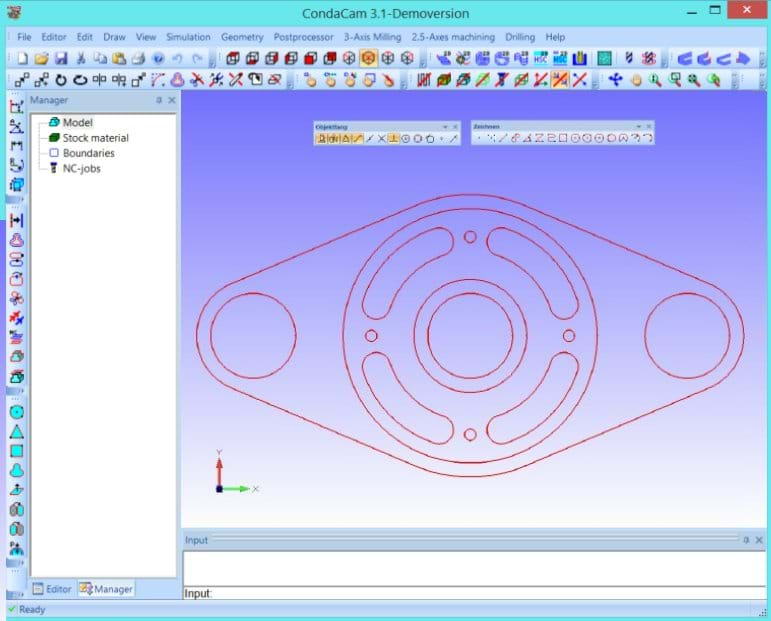

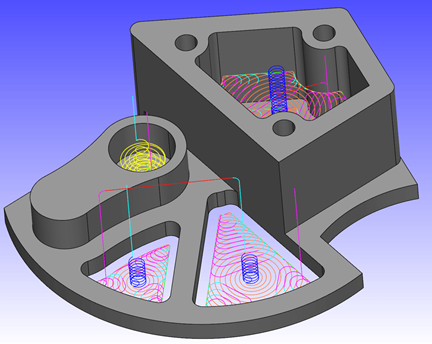

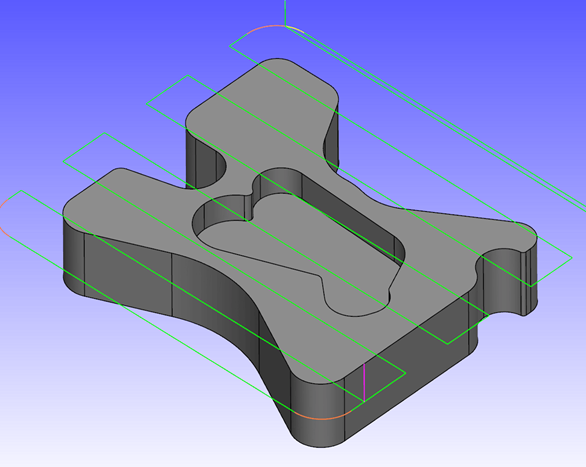

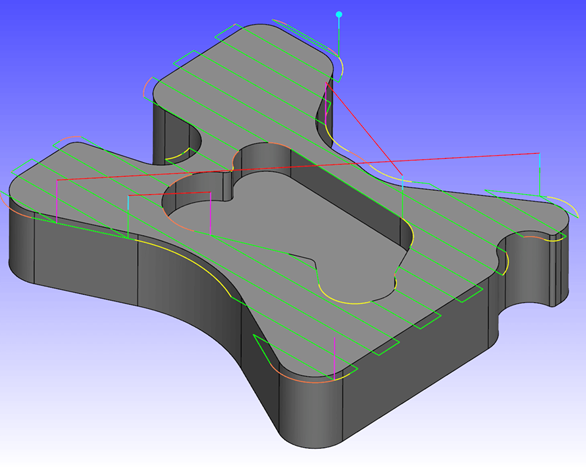

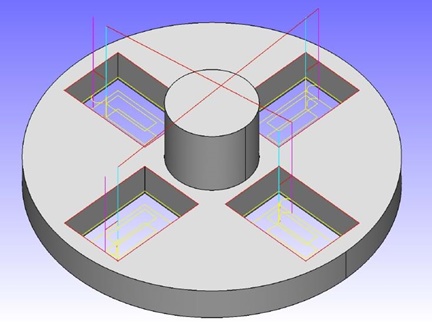

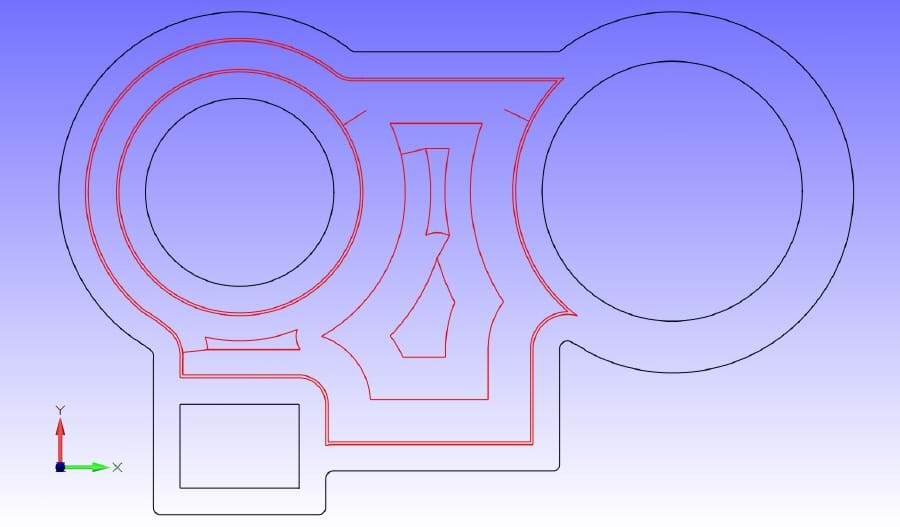

Pocketing

The pocketing supports different methods for clearing such as “offset” and “contour parallel”. This strategy works similar than a roughing strategy by the generation of “clearing paths”. The material is removed or cleared in several steps. For the calculation conduces closed contours from polylines, lines, circles or splines as data basis. Moreover the option for the insertion of finishing cuts still promotes a high surface quality.

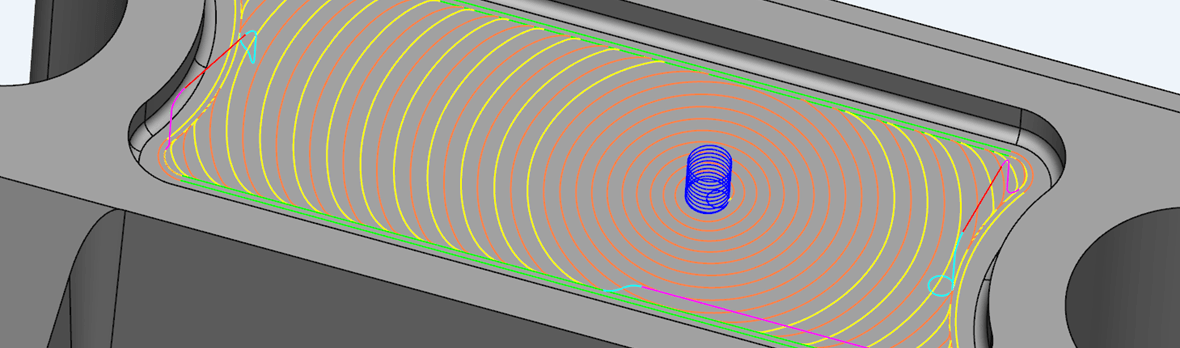

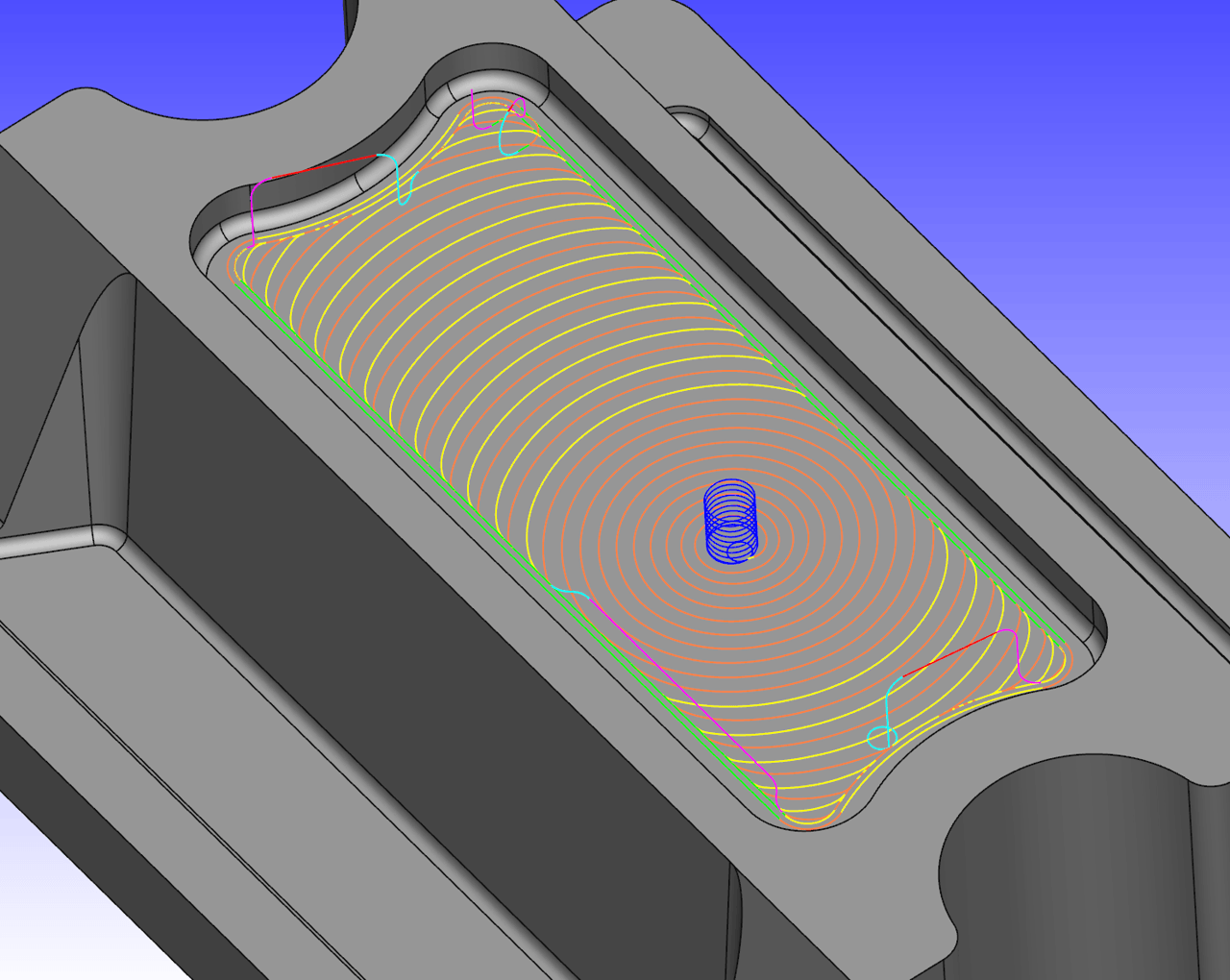

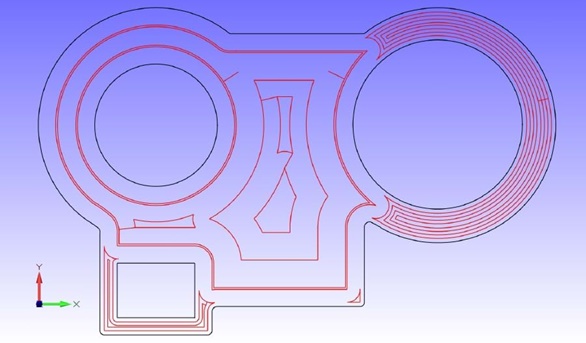

HPC/HSC Pocketing Strategies

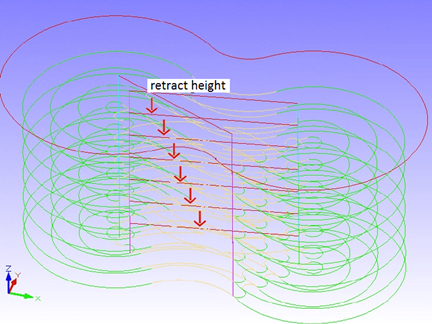

The special feature of the HPC/HSC strategies is opposite to the conventional strategies that the tool load is constantly kept over the entire milling process. Solid carbides can thus be used with high process reliability and feeds with high speed can also be used. The tool life extends, whereby longer milling operations with a tool can be realized.

A further feature of the HPC/HSC strategies is the setting of entry points. By the innovative plunging from slot ramp, helix, simple ramp over the normal plunging you can choice between an automatic or manual calculation of the entry points (including pre-drilling.)

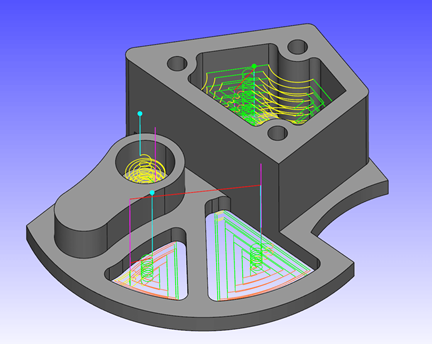

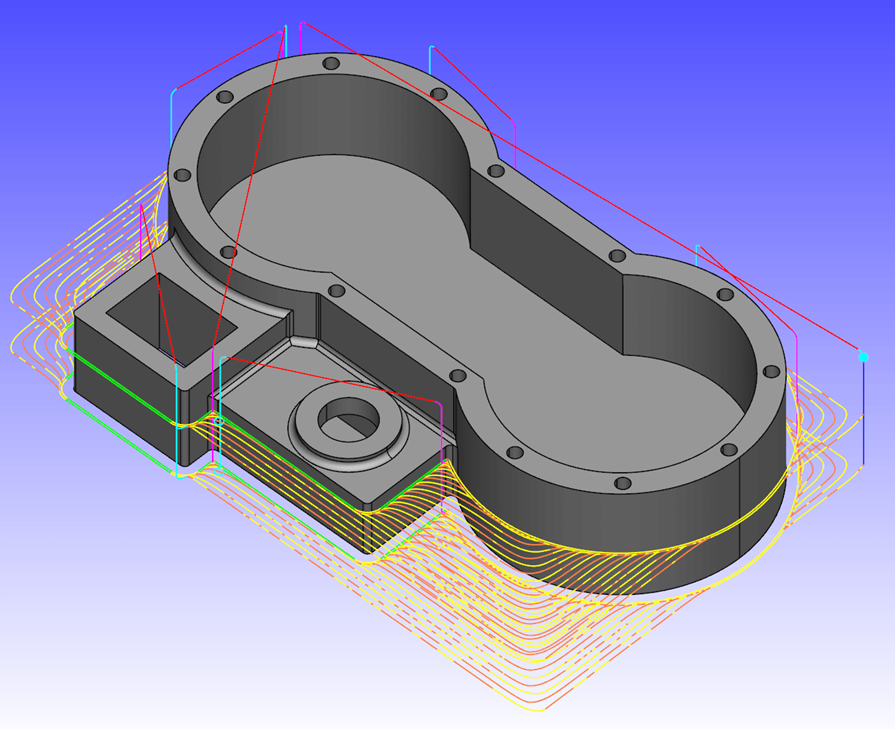

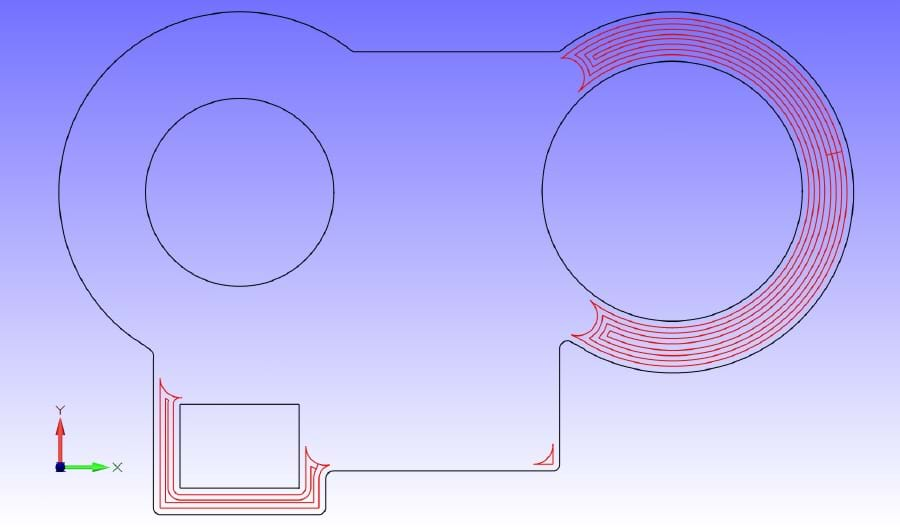

HPC/HSC-Outside Machining

The 2.5D machining strategy HPC/HSC-outside machining is used for removing of material amounts within selected closed machining contours. This strategy works similar than a rough strategy by the generation of clearing paths. Opposite to the conventional strategies the special feature of the HPC/HSC strategies is that the tool load is kept constant over the whole mill process. As a result solid carbides can be used with a high level of reliability and moreover feeds can be used with high speed. The tool life also extends significantly whereby longer lasting mill processes can be implemented with a tool.

Another feature of the HPC/HSC strategies is the setting of entry points. By the innovative plunging over slot ramp, helix, simple ramp and the normal plunging you can choice between an automatic or manual calculation of entry points.

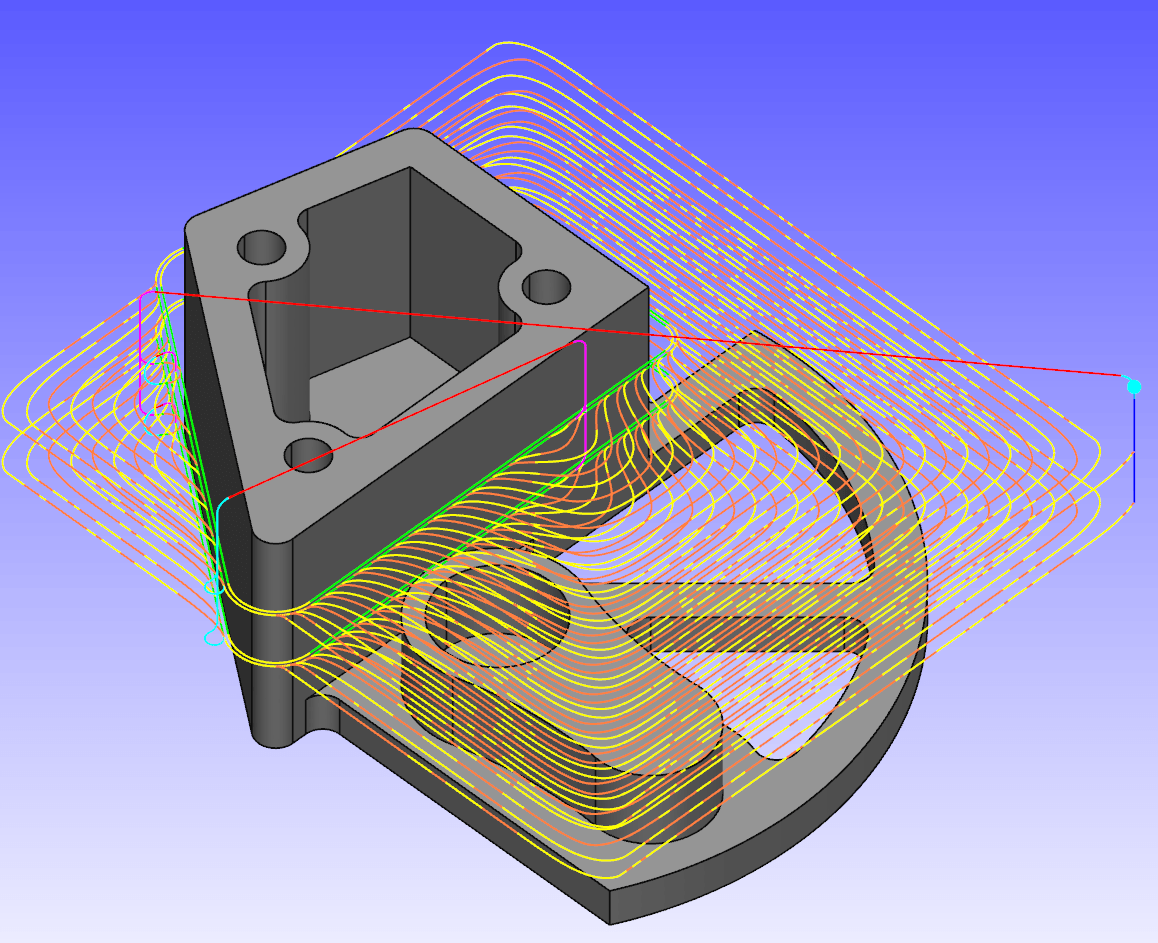

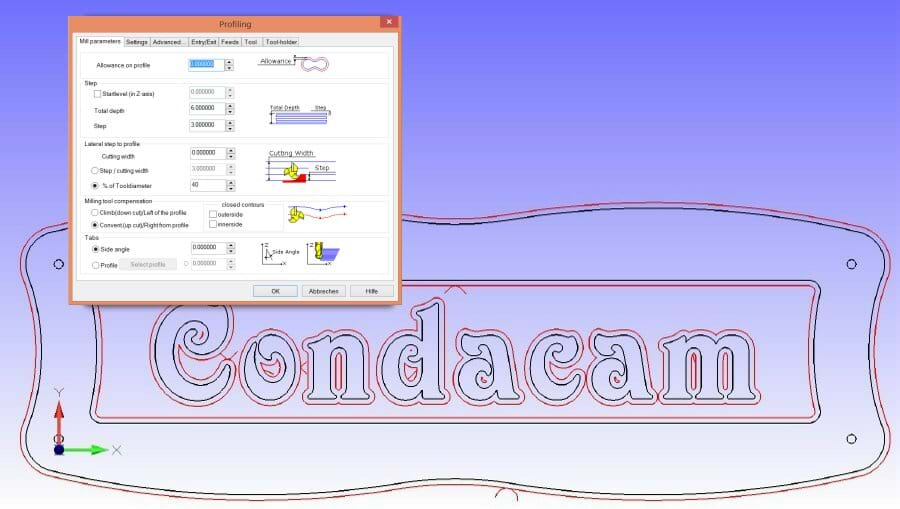

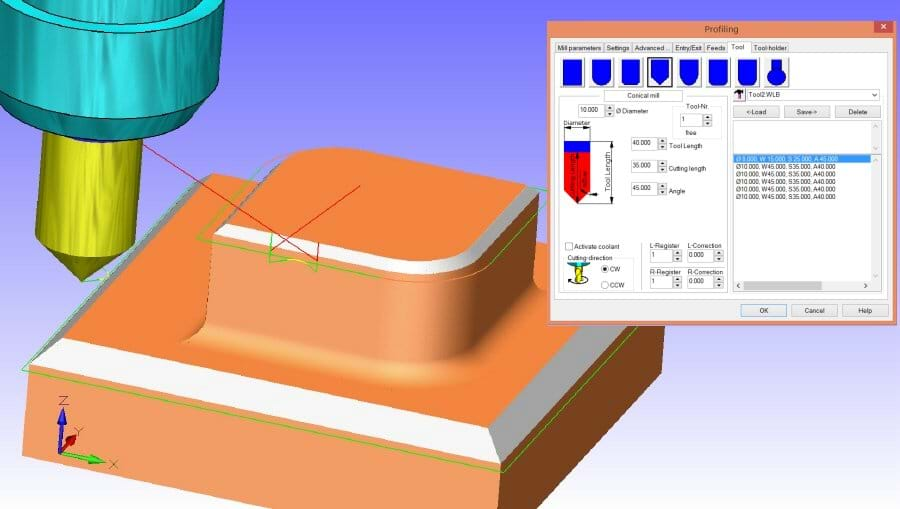

Profile Machining

The 2.5D-machining strategy profile machining is used for the generation of machining jobs with tool radius compensation. Furthermore the profile machining can also conduce as finishing strategy for a preceding roughing (e.g pocketing.) Closed contours such as polylines, lines, circles or splines can be used as data basis for the calculation.

Face Milling

The 2.5 machining strategy face milling is mainly used for the simple generation of plain workpiece surfaces. This strategy acts similar than a roughing strategy by a generation of “clearing paths”. The material will removed by means of this strategy in several steps (in Z). As data basis for the calculation can serve closed contours from polylines, lines, circles or splines.

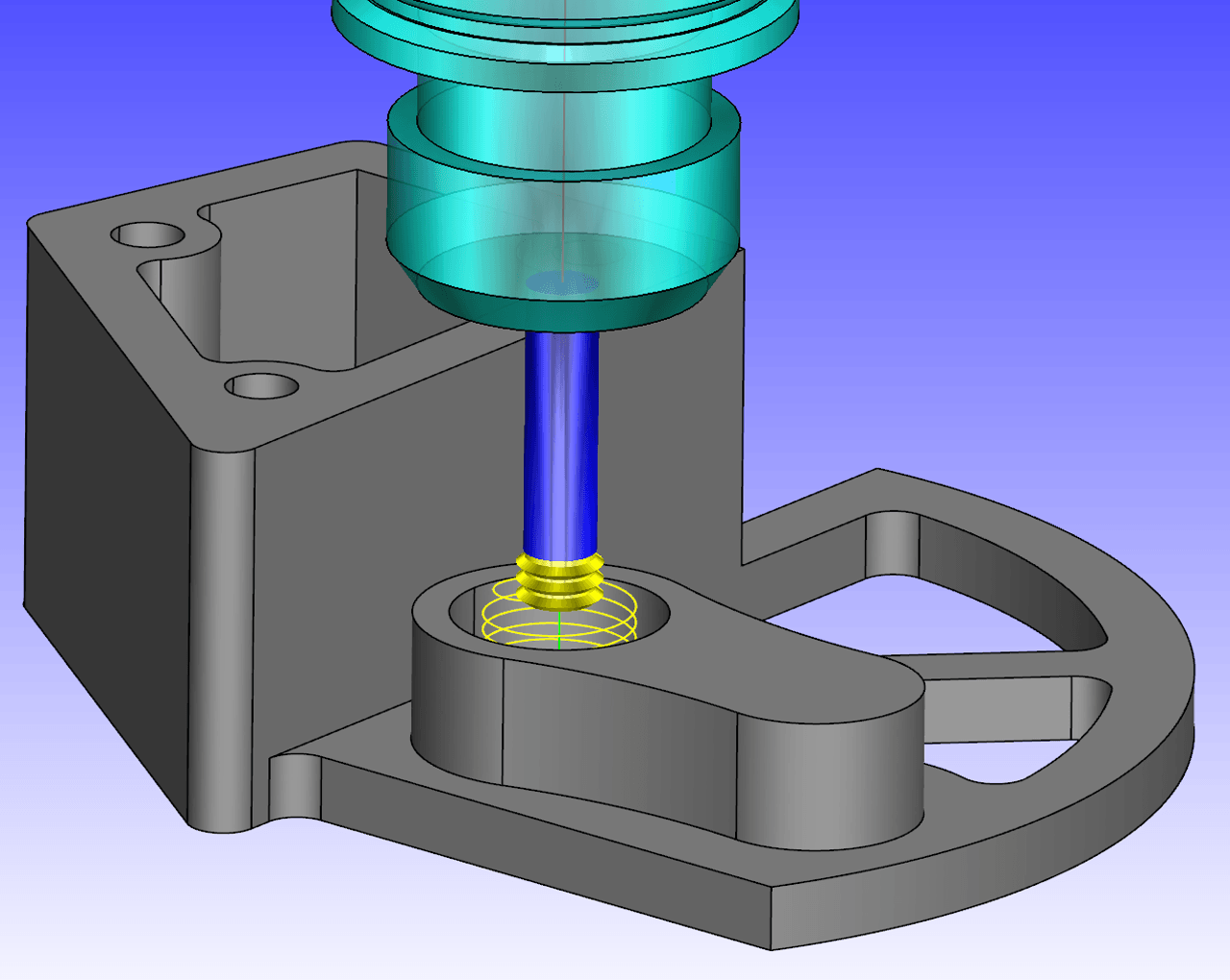

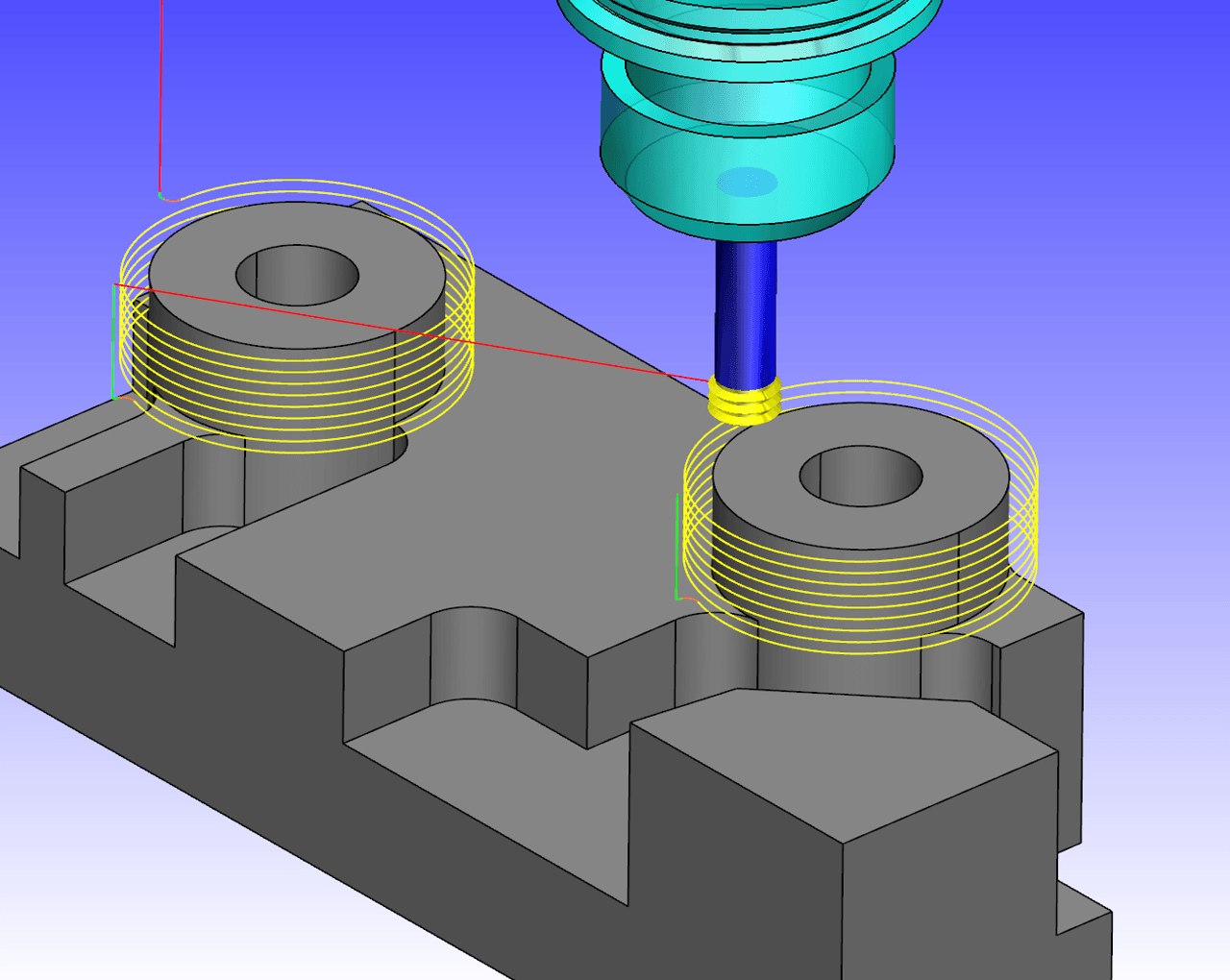

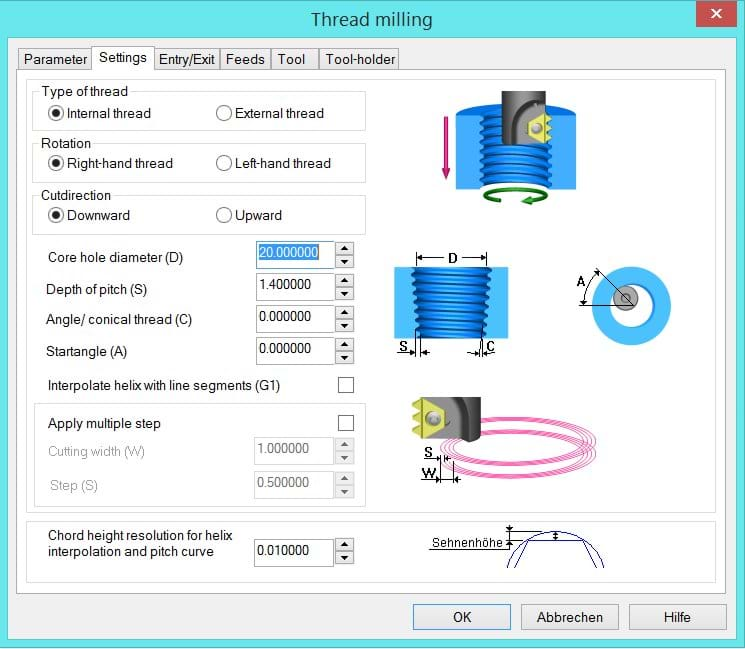

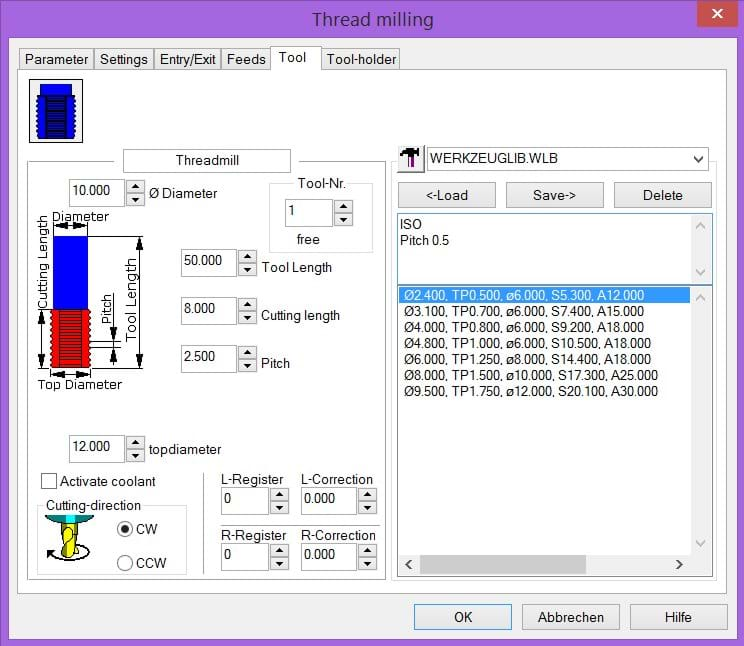

Thread Milling

When thread milling Condacam offers all common methods such as external thread, internal thread as well as the milling of a conical thread. The production of a multi-start thread is also not a problem.

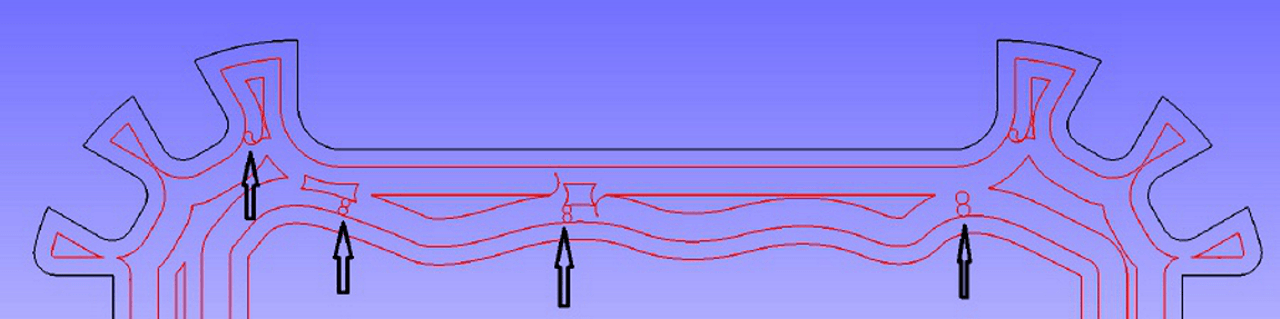

Rest material clearing

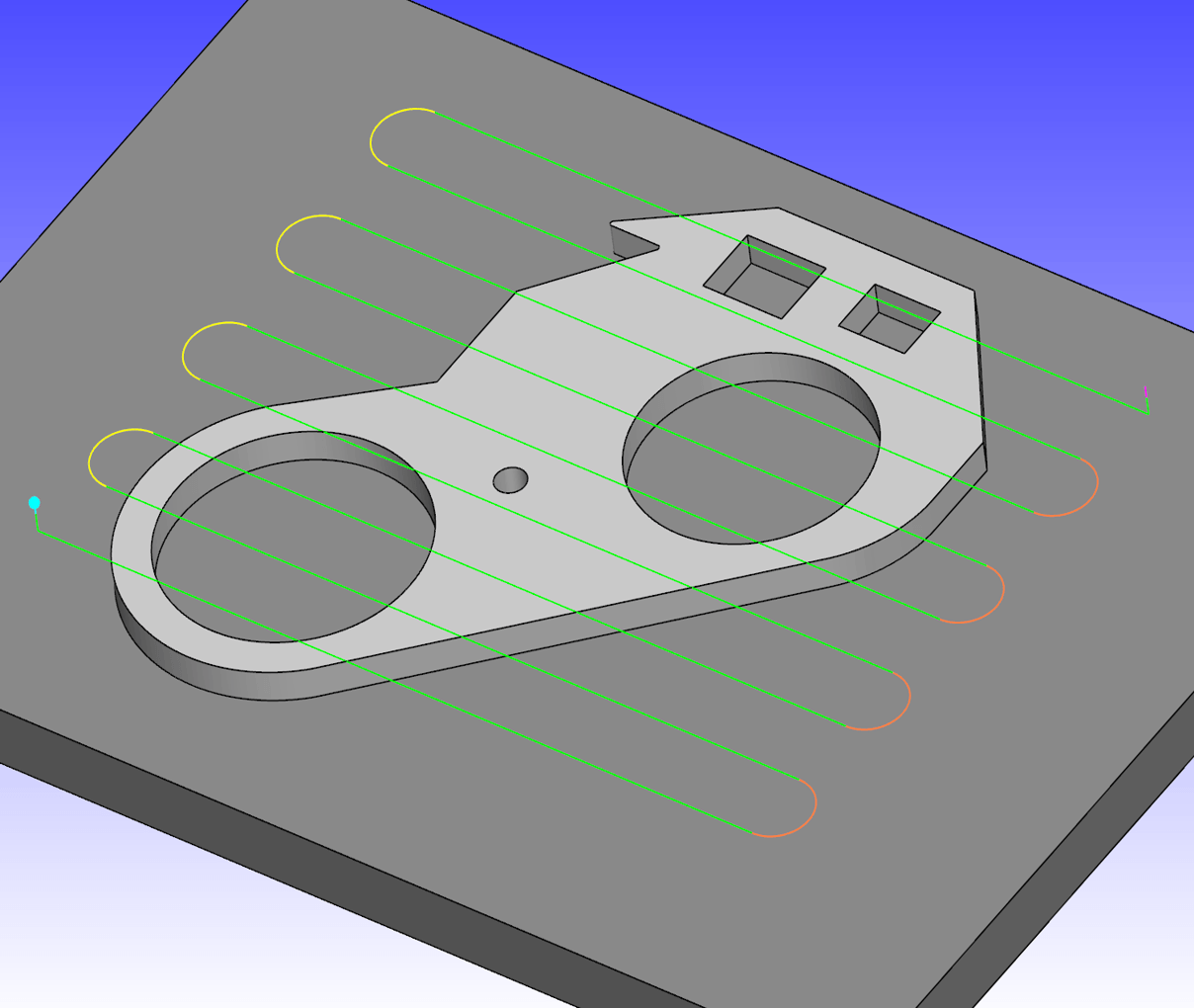

All clearing- or roughing strategies carry out procedures for removing the rest material, what enables a path overlap of more than 50 percent of the tool diameter. The image shows the machining strategy “2D-pocketing” under application of a lateral step (stepover) of 70 % of the tool diameter. Condacam automatically determines where additional cuts are required for the clean-up of rest material.

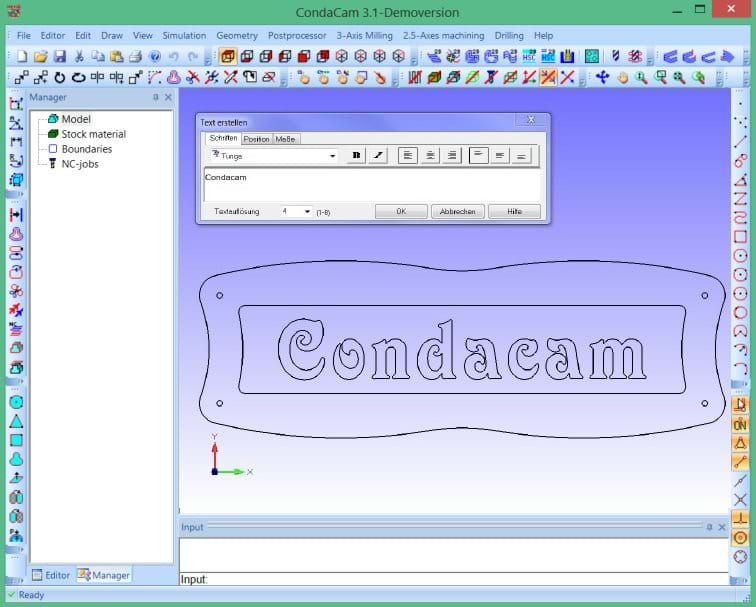

Linies, Polylinies, Arcs

All wire geometries such as lines, polylines, text and circular arcs let be changed or created via the edit functions. 2D-drawings can also be created within Condacam. The construction functions are continuously applicable with object snap support. Even the generating and milling of Window font is possible with a integrated font editor.